Continuous Controlled Depth Parts Processing

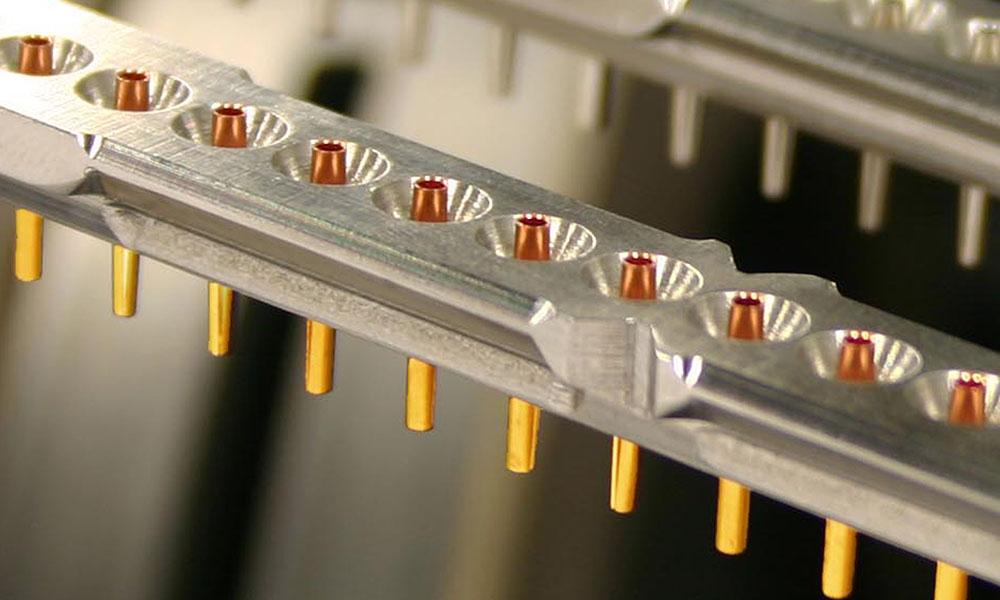

Technic's CDP2000 is a precision electroplating machine designed for high accuracy controlled depth precious metal plating onto loose parts, typically for pins and sockets for the electronic connector industry. Considering that only a small area at the end of the part needs to be electroplated, tremendous savings can be realized when compared with conventional plating methods.

Parts may include:

- Electrical connector pin and socket components

- Spring plunger contacts

- Terminal posts

- Any pin/cylindrical shaped objects manufactured as single components.

Key Design Features

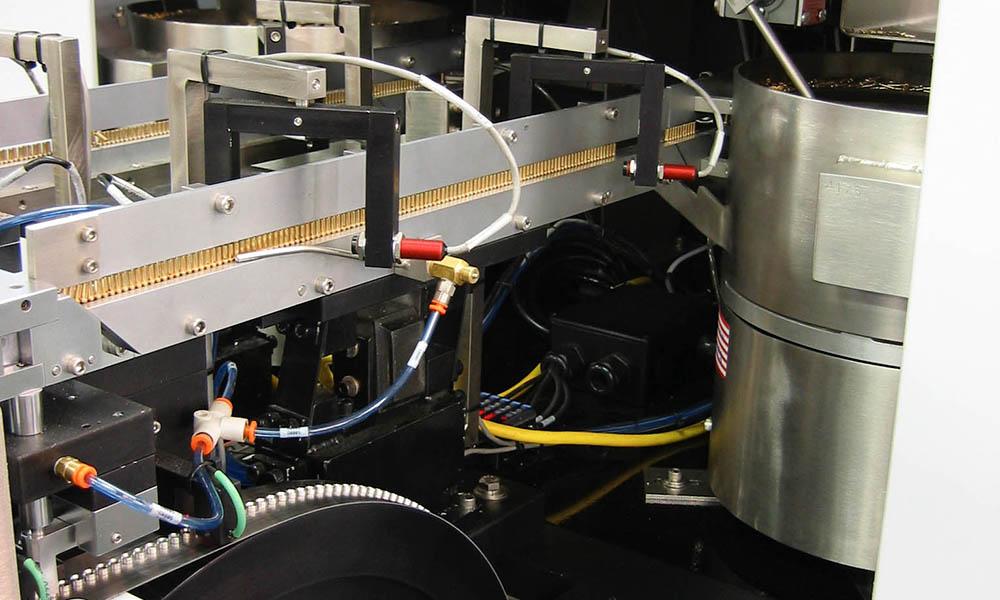

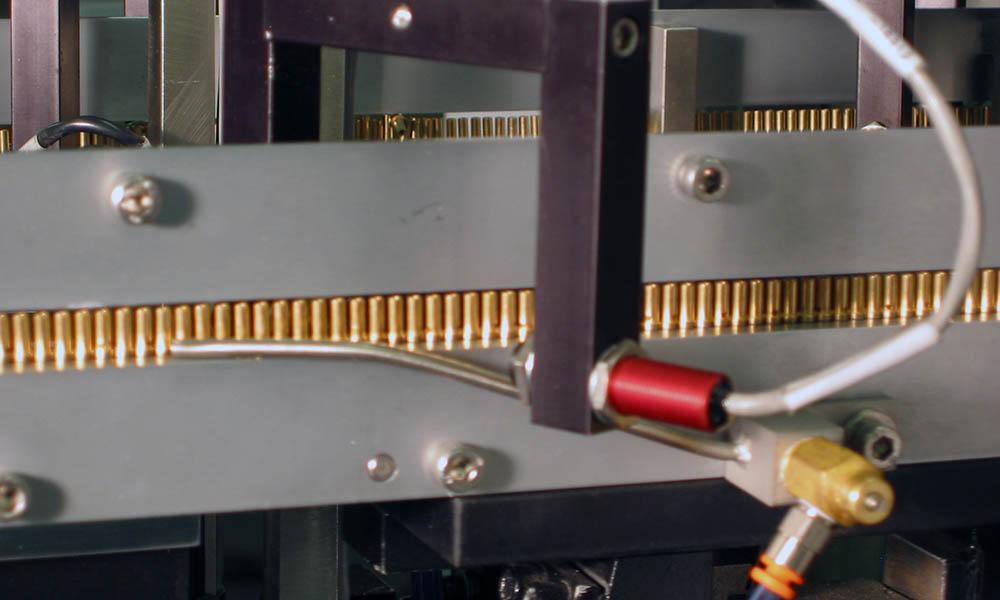

- Transport belts available with permanent inserts or removable cartridges, depending on the volume and required flexibility.

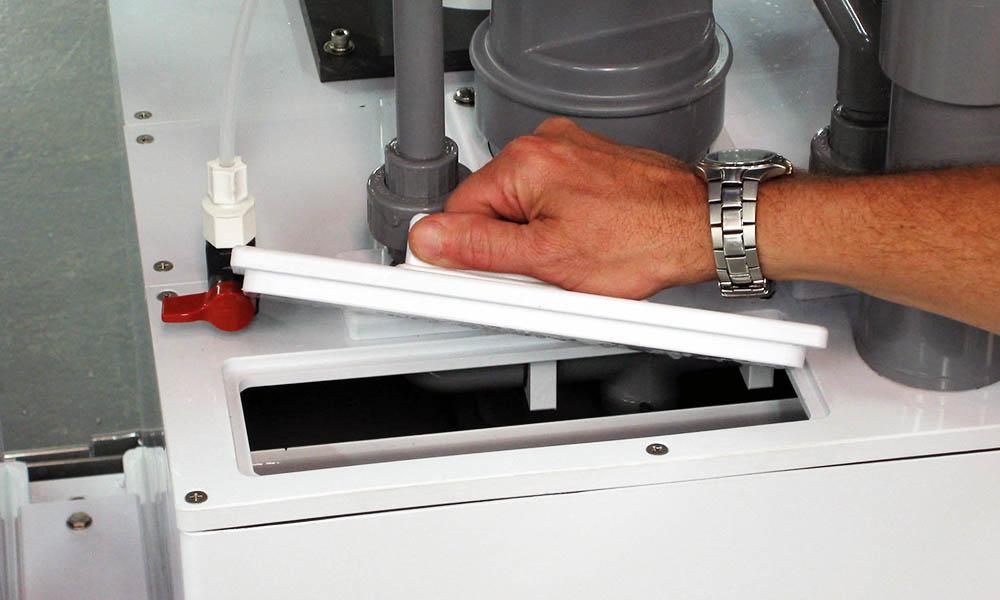

- Dual processing lanes can be configured with the same or two different component configurations. Common chemical reservoirs supply process cells in each lane.

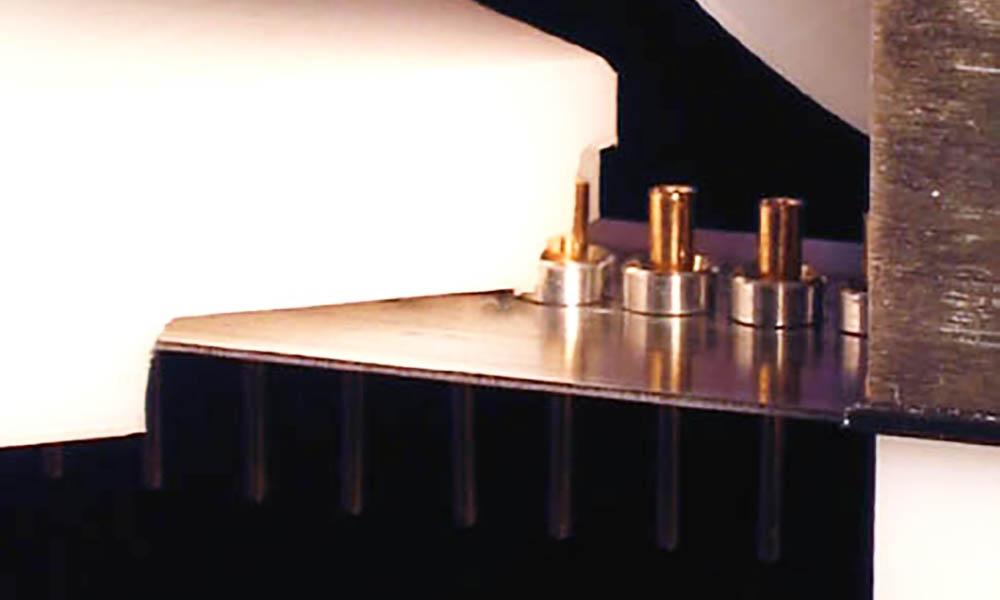

- Plating cells utilize precision fluid flow and level controls to produce controlled depth repeatability to within 0.5mm.

- Menu driven computer reconfigurable anodes provide plating flexibility for a variety of part types, including difficult to plate parts requiring high throw into internal recesses.

- Contact roller connects cathode current to transport belt, providing noise-free, low resistance electrical contact with minimal drag and no particle generation.

- Plating cells utilize a synchronized backup conveyor, which provides pressure on each part through the cells for reliable cathode electrical connection in the transport belt.

Features & Benefits

- High, medium, or low volume production - Plated component throughput of 1,000 to 20,000 parts per hour

- Rapid payback with up to 70% gold savings over conventional barrel plated parts

- Unique plating cell and sparging design provides accurate and repeatable plating depth control and consistent part to part thickness uniformity

- Plating cell eliminates the ‘brown ring’ at the demarcation line between controlled depth deposit and base deposit.

Load/ Unload Options

Manual or fully automatic, in-line or off-line loading and unloading of parts is available. Automation is accomplished using various technologies including:

- Vibratory bowl feeders

- Inline conveyor

- Scara robot

- Cassette-to-cassette

Gold Savings Case Study

The summary data presented below is from actual case studies utilizing plating results from the CDP2000. The data demonstrates the achievable savings when using the CDP2000 versus conventional barrel plating technology. Plating thickness profiles used for the calculation of savings are averages of a 20 piece sample size taken from a 200 part run for both parts.

Gold Savings for Pin

- 50m” overall barrel plate*

- 1.2 gm/1000 parts

- Selective plate + Au flash remainder

- 0.54 gm/1000 parts

- Gold savings of 0.66 gm/1000 parts, 55%

- 660 gm or 21 troy oz of Au for 1 million pins

- 19,682€ at 890€/troy oz Au

Gold Savings for Socket

- 50m” overall barrel plate*

- 2.16 gm/1000 parts

- Selective plate + Au flash remainder

- 0.69 gm/1000 parts

- Gold savings of 1.47 gm/1000 parts, 68%

- 1470 gm or 47 troy oz of Au for 1 million pins

- 41,812€ at 890€/troy oz Au

*Assumption based on 50 micro-inches using a barrel vs. selective plating using the CDP2000.