Vibratory Plating: Rack Plating Quality, Barrel Production, Significant Savings

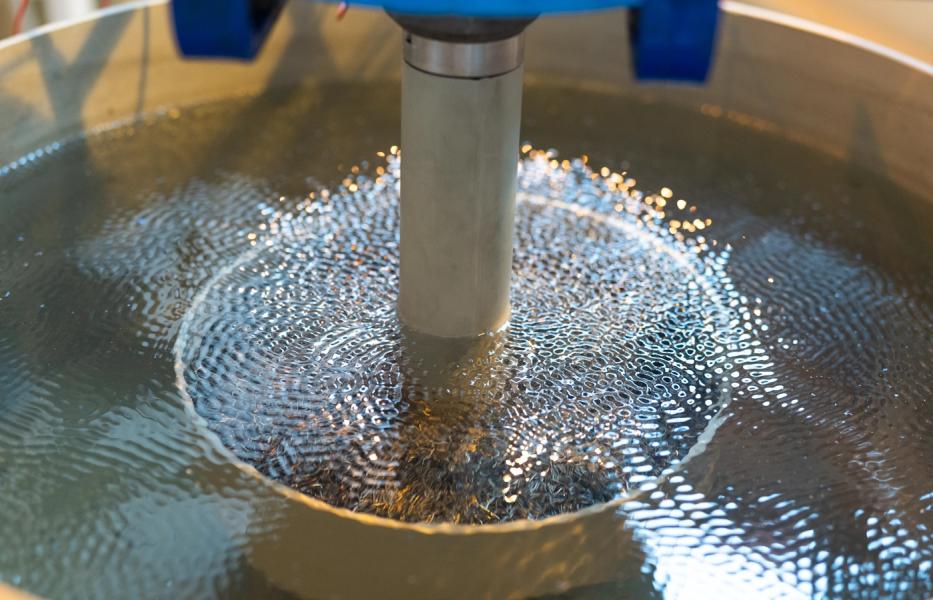

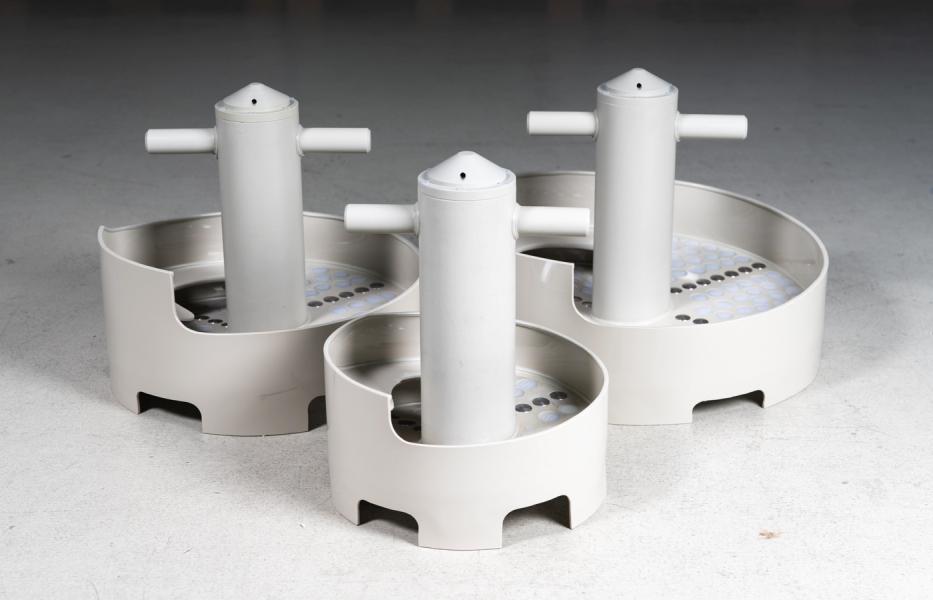

The Vibarrel is a system that provides precise, uniform plating by combining mechanical motion with solution flow. A vertical shaft, driven by a vibration generator, imparts gentle oscillations to a specially designed basket. Parts move slowly and evenly, keeping electrical contact with cathode points, while solution flows through plastic screens.

As the exclusive North American provider of STS Industries’ Vibarrel® series, Technic provides consistent results for precise finishing and plating of delicate parts. We combine the right equipment with optimized media, chemistry, and seamless line integration—plus expert installation, operator training, and ongoing service—so you achieve consistent quality, higher throughput, and reduced costs.

Key Benefits

Lower precious metal use: Uniform plating reduces consumption & ensures coverage in blind areas.

Protects delicate parts: Gentle vibratory action prevents tangling, scratches, and deformation.

Less drag-out: Vibrations-free trapped solution, improving rinsing and lowering waste.

Line-ready: Lightweight, quiet units integrate easily into manual or automated plating lines.

Quick basket change: Open basket design allows inspection; available in PP or PVDF with optional mesh covers.

For more information, email us or call us at 401-721-2300

Available Models & Specifications

Vibarrel 101

- Height/Length/Width: 480 mm (18.9 in)

- Basket diameter: (PP/PVDF/Ti): 60/90/120/160 mm (3.5/6.3 in)

- Weight: 3.8 kg (9 lbs.)

- Power supply: 110/230 VAC – 50 Hz / 24 VDC

- Basket volume: max. 0.3 dm³ (0.01 ft³)

- Max. cathodic amperage: 25 A

Vibarrel 203

- Height/Length/Width: 540 × 315 × 315 mm (21.3 × 12.4 × 12.4 in)

- Basket diameter: (PP/PVDF/Ti): 90/160/200 mm (3.5/6.3/7.9 in)

- Weight: 18 kg (40 lbs)

- Power supply: 110/230 VAC – 50 Hz / 24 VDC

- Basket volume: max. 2 dm³ (0.07 ft³)

- Max. cathodic amperage: 100 A

Optional: Control and monitoring via wireless communication (WLNU, Wireless Network for UT).

Vibarrel 303

- Height/Length/Width: 675 × 758 × 450 mm (27 × 30 × 18 in)

- Basket diameter: (PP/PVDF/Ti): 160/200/250/315 mm (6.3/7.9/9.8/11.8/14.2 in)

- Weight: 50 kg (110 lbs)

- Power supply: 110/230 VAC – 50 Hz / 24 VDC

- Basket volume: max. 4 dm³ (0.15 ft³)

Max. cathodic amperage: 350 A

Optional: Control and monitoring via wireless communication (WLNU, Wireless Network for UT).

Vibarrel 453

- Height/Length/Width: 750 × 956 × 590 mm (30 × 38 × 23 in)

- Basket diameter: (PP/PVDF/Ti): 250/315/360/400/450 mm (9.8/11.8/14.2/15.7/17.7 in)

- Weight: 120 kg (265 lbs)

- Power supply: 110/230 VAC – 50 Hz / 24 VDC

- Basket volume: max. 8 dm³ (0.3 ft³)

Max. cathodic amperage: 800 A

Optional: Control and monitoring via wireless communication (WLNU, Wireless Network for UT).