Photoresist Strippers, Metal Etchants & Cleaners

In semiconductor fabrication, precision chemical processing is essential for reliable device performance. With decades of expertise in wet processes, Technic is recognized as a trusted leader in providing high-performance chemistries for a variety of substrates used in wafer level surface preparation.

Our portfolio is focused on three core product lines:

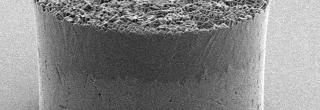

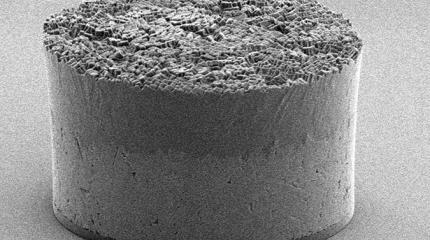

- Photoresist strippers (resist removers, lift-off chemistries) – Formulated for the controlled removal of photoresist and other temporary masking layers after lithography. These products ensure complete removal of both liquid and dryfilm resist, while preserving underlying films and device features.

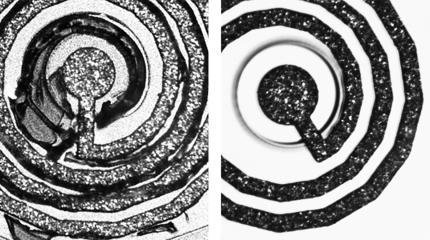

- Metal etchants (material removers, pattern transfer chemistries) – Designed for the selective removal of metals, oxides, and other thin films. Etchants enable accurate pattern definition and surface shaping required for device structures.

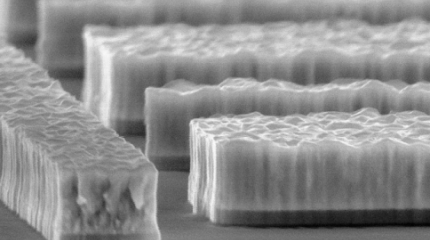

- Cleaners (surface preparation solutions, particle/residue removers) – Developed to eliminate particles, organic films, and trace metallic contamination at multiple process steps. Cleaners prepare wafer surfaces by removing contaminants that could interfere with subsequent deposition, etching, or bonding processes.

Through continuous R&D, including European-level collaborative projects, Technic is actively developing safer alternatives to traditional wet process chemistries. These innovations help customers reduce the environmental impact of their processes through improved waste management, direct water rinsing, eco-design, and reclaimable chemistries.

Photoresist Strippers

Technic supplies photoresist strippers for full dissolution and/or lift off of all types of photoresist resins. These strippers provide high performance without the use of harmful chemicals like NMP. Our industry-leading TechniStrip® products offer high metal compatibility and an extended bath life and can be used in all types of production stripping tools.

Metal Etchants

Technic's proprietary etchants are being used around the world in various applications. They provide very high metal selectivity and a long bath life and are formulated to meet the challenges of advanced technology in the fabrication and packaging industry.

Cleaners

Technic offers proprietary solutions for Post Etch Residue (PER) cleaning. These chemically safe cleaners have extremely high metal compatibility for a wide variety of substrates and can be used in all types of production tools.