Controlled Depth Pin Plater for Precision, Efficiency, and Gold Savings

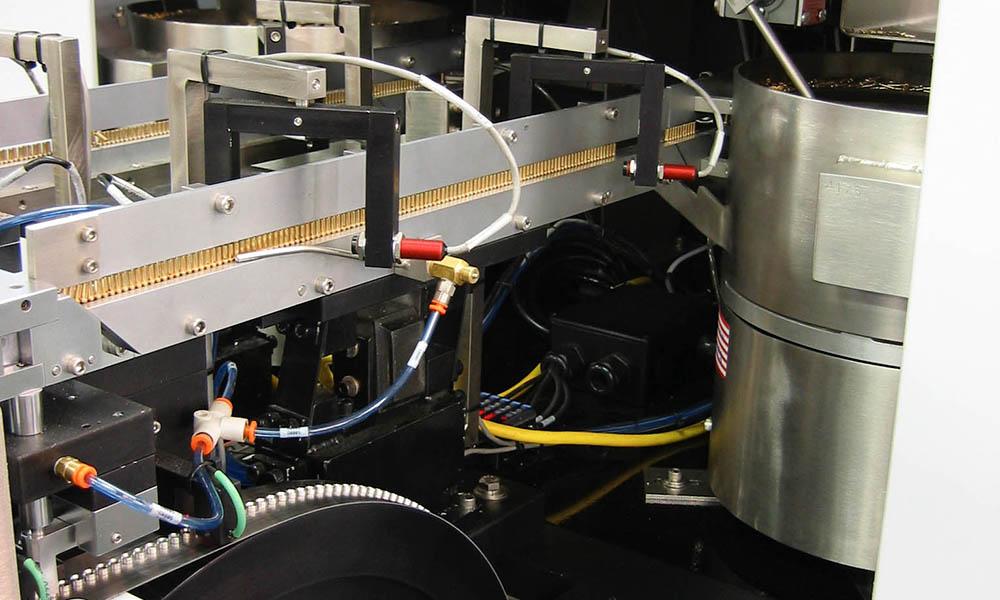

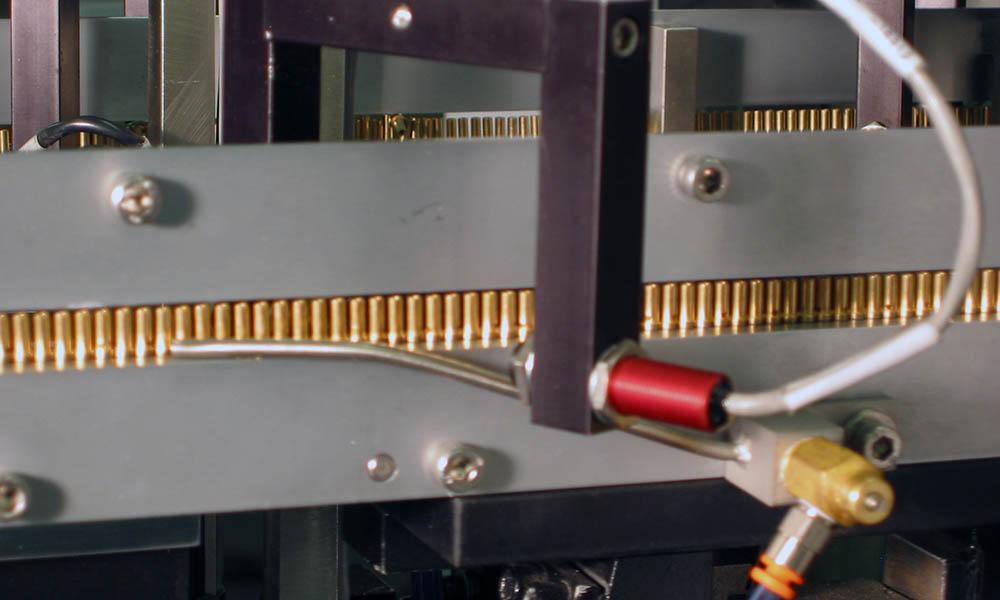

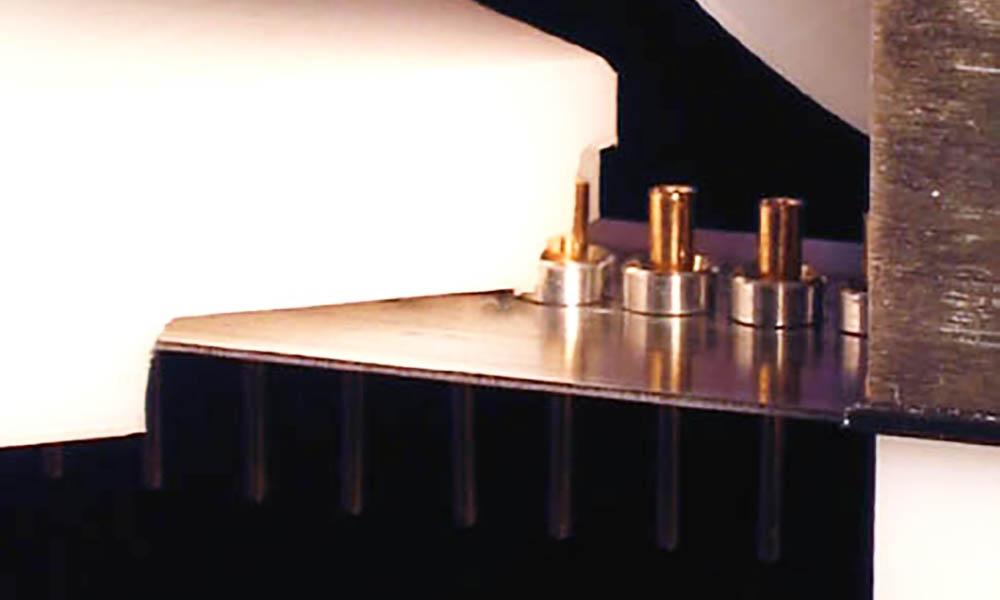

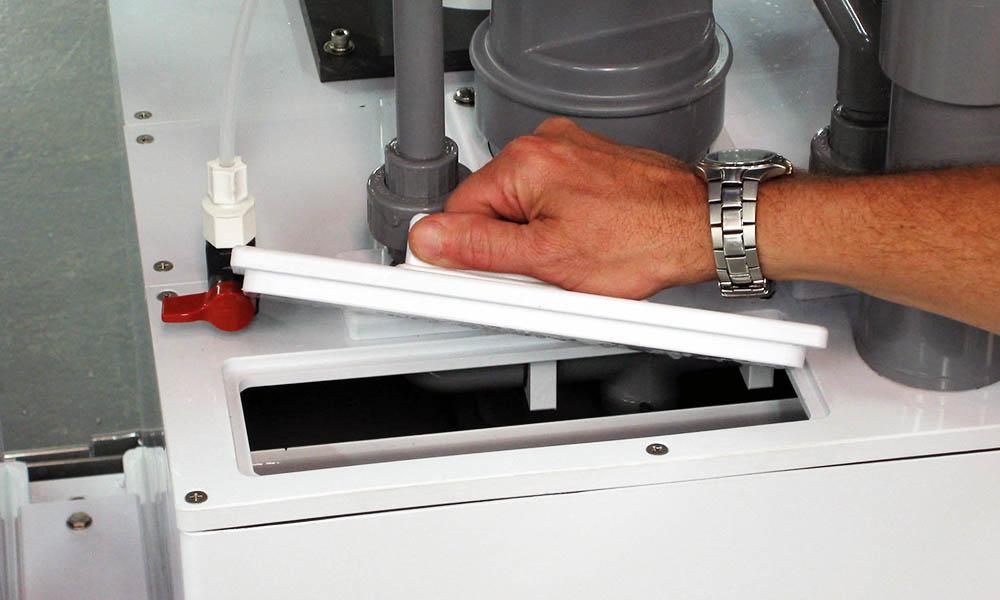

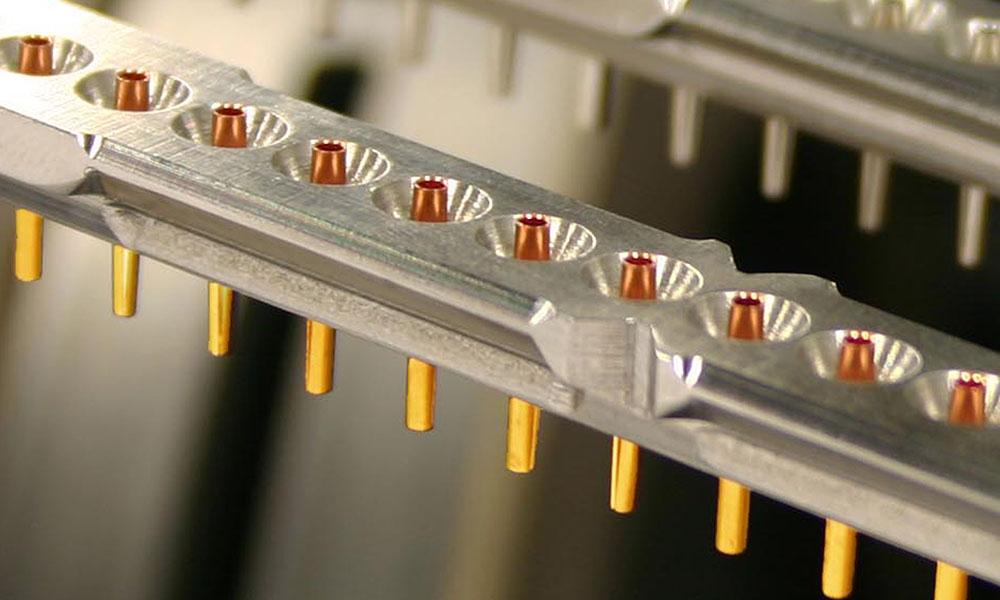

Technic's CDPP (Controlled Depth Pin Plater) is a high-precision electroplating system engineered to plate only the functional contact areas of electrical connector pins and sockets. Designed specifically for loose electrical connector components, the CDPP delivers exceptional depth accuracy, uniformity, and significant gold savings compared to conventional barrel plating.

The CDPP combines advanced fluid dynamics, programmable anode technology, and reliable cathode contact to deliver repeatable, controlled-depth plating with exceptional consistency. Its proprietary cell design ensures clean demarcation between plated and unplated areas, eliminating common defects such as “brown ring” formation.

Ideal applications include electrical connector pins and sockets, spring-plunger contacts and terminal posts.

Key Benefits

- Reduces precious-metal usage by up to 70% compared to barrel plating

- Scalable throughput up to 20,000 parts per hour

- Consistent depth control and deposit uniformity

- Clean demarcation lines with no interface defects

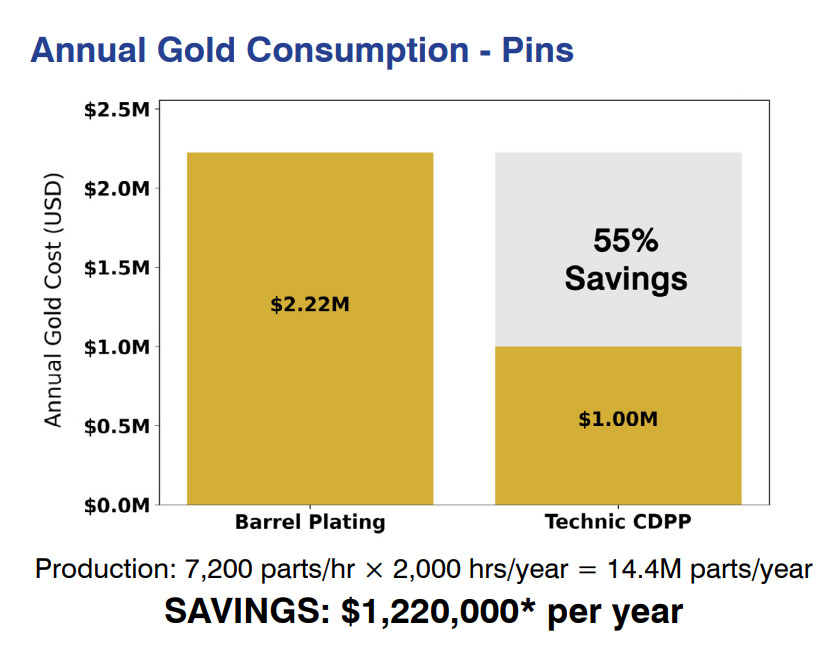

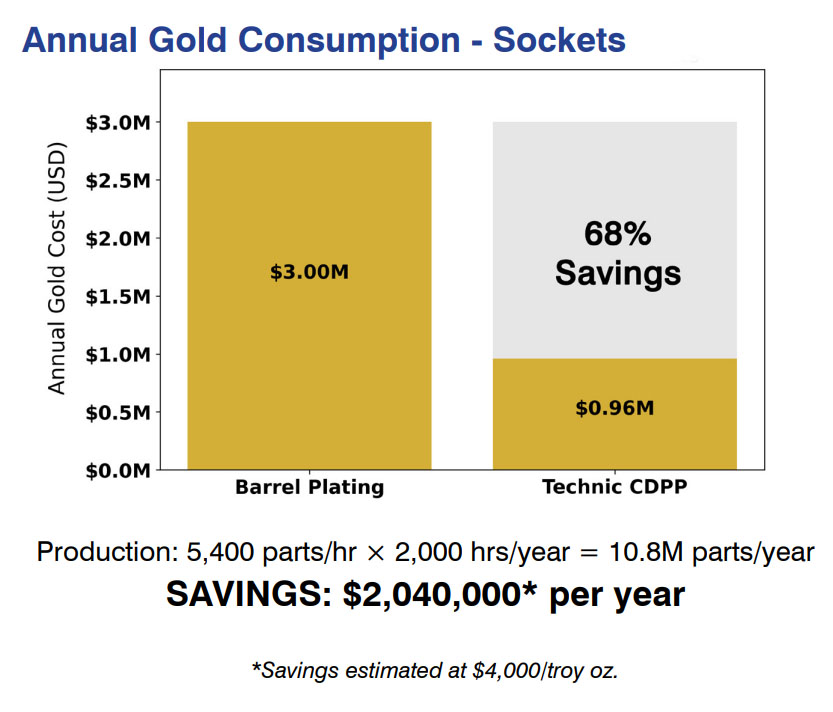

Gold Savings Case Study

Demonstrated savings below are based on actual production runs using Technic’s CDPP vs. conventional barrel plating (50 micro-inch thickness).