How the SBE Chamber Works

Advantages in Performance and Maintenance

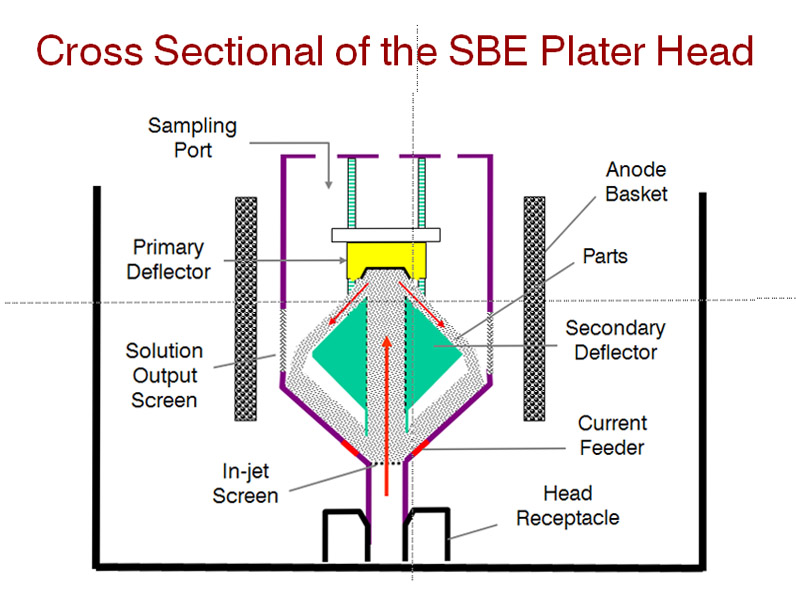

Technic's SBE® plating chamber features a proprietary design that rapidly circulates parts over the cathode current feeder without any mechanical movement. Parts are carried through the chamber by high-speed plating solution flow, up to 60 liters per minute, ensuring they are always exposed to fresh solution, regardless of size or shape.

This continuous, high-flow circulation results in:

-

Superior part-to-part thickness uniformity

-

Significantly reduced part coupling and clustering

Thanks to its tighter thickness distribution, the SBE® system allows SMT manufacturers to plate parts much closer to the minimum required thickness, reducing metal usage and increasing process efficiency compared to traditional barrel plating systems.

Thanks to its tighter thickness distribution, the SBE® system allows SMT manufacturers to plate parts much closer to the minimum required thickness, reducing metal usage and increasing process efficiency compared to traditional barrel plating systems.

Additional Advantages:

-

Faster production speeds while maintaining strict quality standards

-

Reduced maintenance: Unlike barrels, the SBE® screens are located in non-plating zones, eliminating unwanted tin or nickel buildup on the screens and simplifying chamber cleaning

The SBE® is not just a plating system—it's a proprietary breakthrough in precision, efficiency, and reliability for high-performance electronic component finishing.