ENIG

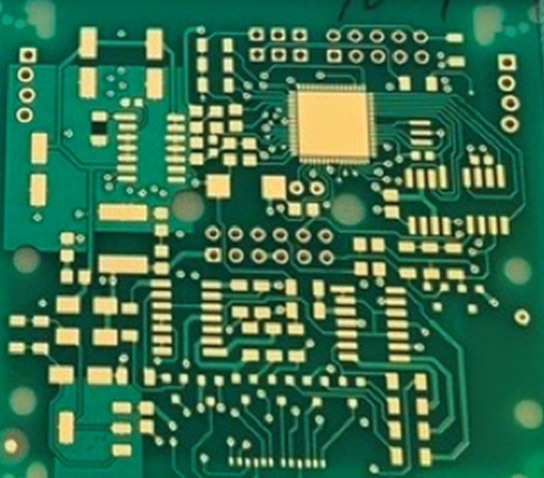

The most used Final finish because of harsh environment resistance and solderability. Technipad ENIG is the most effective ENIG quality/cost process on the market.

TechniCatalyst AT4608 is a chloride-free, organo-metallic activator specifically designed to produce an immersion palladium deposit for the complete and uniform initiation of electroless nickel such as Techni EN AT 5600 or EN D 5810 on Copper and Copper alloys.

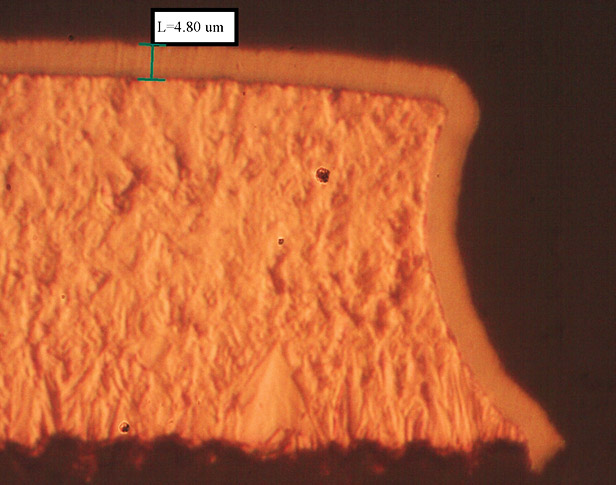

Technic EN AT 5600 is an advanced, electroless nickel that produces a deposit with 6 – 9% w/w phosphorus. It is specifically formulated for use with TechniPad ENIG and TechniPad ENEPIG processes for printed circuit boards and meets IPC4552 A and B. Unlike competitive processes, Technic EN AT 5600 provides better lateral growth on copper yielding better corrosion resistance and superior solderability.

Download the TechniPad ENEPIG Fact Sheet

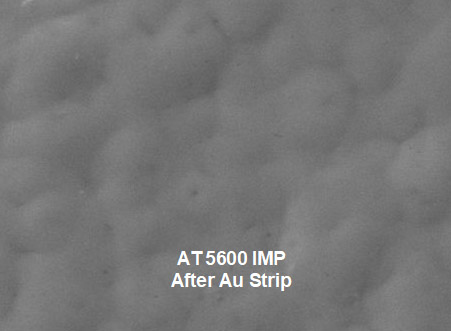

![]() Technic EN AT 5600 process is uniquely formulated to minimize reaction by-product buildup and, as a result, this process has a dramatically longer bath life. Technic EN AT 5600 also features an advanced stabilizer system that provides excellent solution stability throughout the life of the solution, thus eliminating the need for “break-in” periods or minimum loading concerns.

Technic EN AT 5600 process is uniquely formulated to minimize reaction by-product buildup and, as a result, this process has a dramatically longer bath life. Technic EN AT 5600 also features an advanced stabilizer system that provides excellent solution stability throughout the life of the solution, thus eliminating the need for “break-in” periods or minimum loading concerns.

![]() Technic EN 5810 is an advanced, electroless nickel process that produces a deposit with 10 – 13% w/w phosphorus. This lead and cadmium-free process is specifically formulated for use with TechniPad ENIG and TechniPad ENEPIG processes for printed circuit boards and meets IPC4552 A and B. Unlike competitive processes, Technic EN 5810 provides better lateral growth on copper yielding better corrosion resistance, superior solderability, and low insertion loss for specific 5G applications. At 1/3 of the normal thickness for Nickel, it meets all the same corrosion specs, reduces the normal insertion loss for EN by half, and is more flexible. It produces a Non-magnetic deposit.

Technic EN 5810 is an advanced, electroless nickel process that produces a deposit with 10 – 13% w/w phosphorus. This lead and cadmium-free process is specifically formulated for use with TechniPad ENIG and TechniPad ENEPIG processes for printed circuit boards and meets IPC4552 A and B. Unlike competitive processes, Technic EN 5810 provides better lateral growth on copper yielding better corrosion resistance, superior solderability, and low insertion loss for specific 5G applications. At 1/3 of the normal thickness for Nickel, it meets all the same corrosion specs, reduces the normal insertion loss for EN by half, and is more flexible. It produces a Non-magnetic deposit.

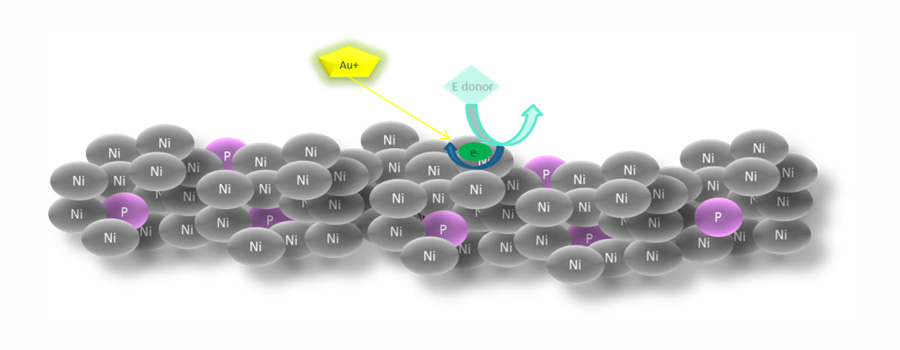

TechniPad Au 6100 is a cyanide-based immersion gold plating process designed to provide a controlled deposition of thin pure gold deposits onto electroless nickel and electroless palladium. The gold deposition is controlled using proprietary additives which eliminate corrosion products on the nickel-gold interface that can form with PGC-based immersion gold. Elimination of these corrosion products provides a dramatic improvement in solderability over other processes. Deposits are uniform, fine-grained, and exhibit extremely low porosity. The solution has excellent pH buffering capacity and high tolerance to copper, nickel, and lead contamination. When used with the TechniPad ENIG or Technipad ENEPIG process, it is possible to operate at lower gold concentrations in the operating solution due to the flat electroless nickel deposit. An overall saving in gold consumption is possible if the entire TechniPad process is used.

![]() Techni IM Gold AT8000 is a cyanide-free process that produces thin, adherent, pure gold immersion deposits onto electroless nickel substrates. Deposits are uniform and fine-grained with low porosity. The solution exhibits excellent pH buffering capacity and has a high tolerance from contamination. The deposits are solderable and sufficiently thick to maintain solderability over prolonged storage periods. Techni IM Gold AT8000 can provide gold savings by operating at lower gold concentrations and by providing excellent thickness distribution over different feature sizes. Techni IM Gold AT8000 can replace any cyanide base immersion Gold for ENIG application.

Techni IM Gold AT8000 is a cyanide-free process that produces thin, adherent, pure gold immersion deposits onto electroless nickel substrates. Deposits are uniform and fine-grained with low porosity. The solution exhibits excellent pH buffering capacity and has a high tolerance from contamination. The deposits are solderable and sufficiently thick to maintain solderability over prolonged storage periods. Techni IM Gold AT8000 can provide gold savings by operating at lower gold concentrations and by providing excellent thickness distribution over different feature sizes. Techni IM Gold AT8000 can replace any cyanide base immersion Gold for ENIG application.

Illustration: mechanism of ion exchange.

Request more information on our Enig products for PCB

TechniPad Au 6100 and Techni IM Gold AT 8000

Features

• Lowest cost on the market

• Easy to maintain

• Extreme long life, up to 20 MTO

• Smallest variation from pad to pad

• Does not discolor the white solder mask

Benefits

• Excellent distribution

• Uniform gold deposit

• Better sealed surface

• Eliminate corrosion

• Pass the IPC 4552 A and B spec

• Stable and extremely long life