Technic Solar Solutions

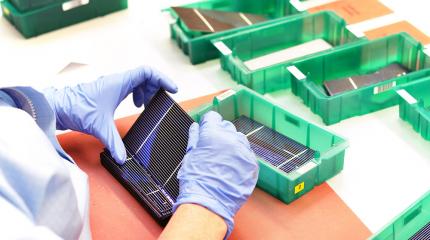

While Technic continues to provide the highest quality, finely engineered powders and flakes for solar applications, we also provide several electroplating solutions specifically formulated to form plated metal contacts on solar cells. Our electroplating solutions for solar cell manufacturing, marketed under the name TechniSol®, are silver-free, offering a lower cost option with excellent efficiency results.

Advantages of Electroplated Contacts with TechniSol®

Plated contacts in solar cell manufacturing can achieve several key advantages over silver paste contacts:

- <40-micron grid lines

- 50% lower gridline contact resistance

- Twice the grid line conductivity

- 25% or more cost reduction

- Higher pull-strengths resulting in better adhesion

- Repeatable cross-sectional shape when compared to double-print grid line

- A minimum of 0.5% increase in efficiency

Technic’s TechniSol® plating chemistries can be used for standard front side contact cells and also for advanced cell structures such as bifacial and heterojunction.

Downloadable Files

TechniSol® Nickel 2428

- Novel Boric Acid-Free Nickel Chemistry developed to plate Ni on silicon solar cells using LIP with or without rectification.

- This chemistry is very stable and requires little maintenance.

- Nickel deposited from this bath has low stress and good diffusion barrier properties. Solar cells plated with this chemistry show similar electrical performance and peel test performance (good adhesion) to silver paste controls.

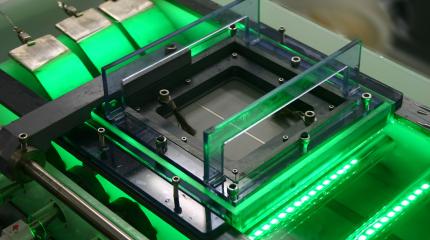

TechniSol® Cu 3000

- Produces low-stress deposits which meet the stringent requirements of the photovoltaic industry.

- High plating rates of 3 – 5 microns/minute with good coplanarity

- Wide process window and a stable additive package

- Can be used with Light Induced Plating or electrolytic plating

- All components are easily analyzed with the Technic EBA (Electroplating Bath Analyzer)

- Can be used to plate standard front-side contact cells with Al BSF, PERC, bifacial cells, HJT and most other cell types.

TechniSol® Sn 2480

- Unlike traditional tin plating solutions, this chemistry stays clear throughout the life of the bath making it ideal for LIP. It can also be used for standard electroplating.

- Offers excellent solderability during module assembly.

- Uses a single additive for replenishment which produces tin deposits with extremely low organic levels.