Standard Designs with Customizable Flexibility

The SBE® System is available in two standard models—the 1-6 and 2-6—designed to meet a range of production requirements. For operations with unique or evolving needs, the system can also be custom-configured and expanded, offering scalable solutions tailored to your specific manufacturing process.

1-6 Model

The SBE® 1-6 is a compact, self-contained plating system designed for efficient, high-quality processing of small electronic components.

The SBE® 1-6 is a compact, self-contained plating system designed for efficient, high-quality processing of small electronic components.

It features:

-

Two plating tanks: One for nickel and one for tin plating

-

Two rinse stations follow each plating step

-

Two SBE® chambers for simultaneous processing

-

Integrated system: Includes pumps, filters, rectifiers, all necessary piping, and an exhaust outlet

-

Durable construction: Built from chemical-resistant polypropylene and mounted on a stainless steel base with adjustable leg levelers

This model offers a complete, ready-to-run system for labs or production lines with moderate throughput requirements.

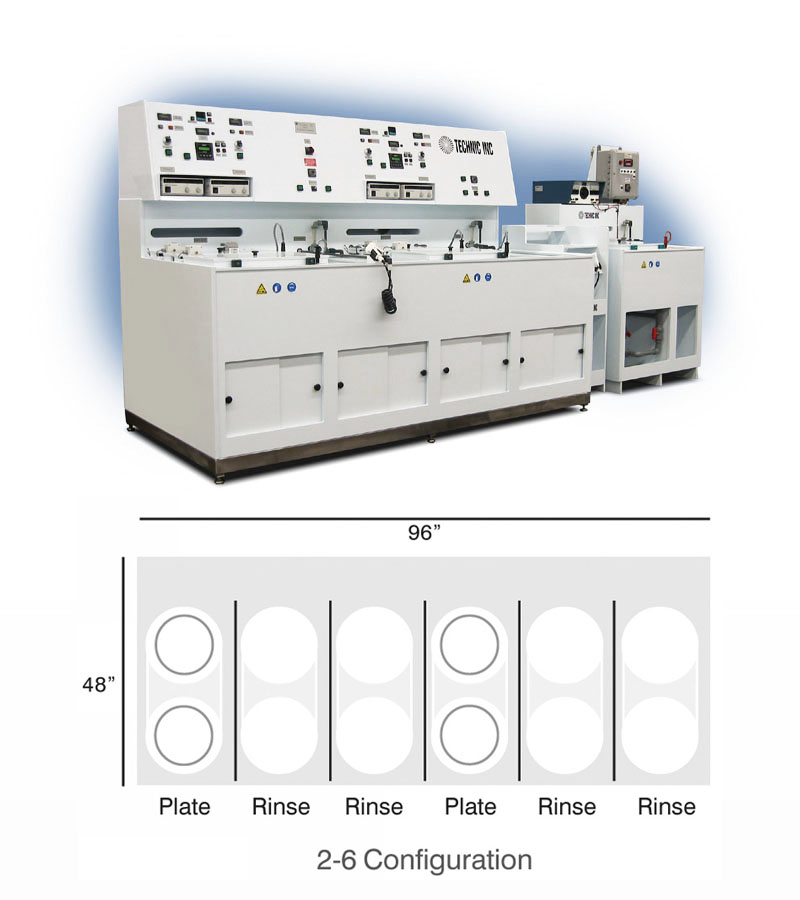

2-6 Model

The SBE® 2-6 is designed for double the production capacity of the 1-6 model.

The SBE® 2-6 is designed for double the production capacity of the 1-6 model.

It features:

-

Two plating tanks (nickel and tin), each with a second row of stations to handle more components simultaneously

-

Four SBE® chambers to maximize throughput

-

All other features and components of the 1-6 model, including pumps, filters, rectifiers, piping, and exhaust

The 2-6 is ideal for high-volume operations seeking greater efficiency and output without expanding the system footprint significantly.

Multi-Process Configurations

Customized for Complex Manufacturing Needs

Technic’s SBE® Systems are fully customizable to support multi-process configurations, enabling seamless integration of multiple plating steps, such as nickel, tin, gold, or other finishes, within a single line. These systems are designed to meet a wide range of complex manufacturing requirements.

For added flexibility, SBE® Systems can be operated in both fully automated and programmable manual modes, giving operators full control when needed while maintaining process consistency and repeatability.

Whether you're automating a full line or need the versatility of manual control, Technic delivers a solution that adapts to your production strategy.