Post Etch Residue Cleaners for Semiconductor Packaging Applications

Technic manufactures a variety of proprietary solutions for Post Etch Residue (PER) cleaning for wafer level surface preparation in semiconductor applications.

Our TechniClean product line is designed to penetrate and dissolve both organic and inorganic post-etch residues, while maintaining excellent compatibility with sensitive metals, dielectrics, and barrier layers. Each product is developed to meet the process integration requirements of advanced node manufacturing, providing superior surface preparation for subsequent deposition or patterning steps, and maintaining the integrity of critical features and structures.

With global technical support and rigorous quality control, Technic help fabs and tool manufacturers meet increasingly tight specifications and productivity targets.

TechniClean CA series

TechniClean CA25, CA585

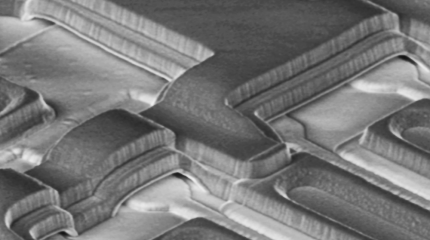

These products are engineered to remove Post-Etch Residues (PER) from Al, Cu, W with high selectivity. Validated alternatives to legacy PER solutions on interconnections, vias, pads, etc.

TechniClean IK73

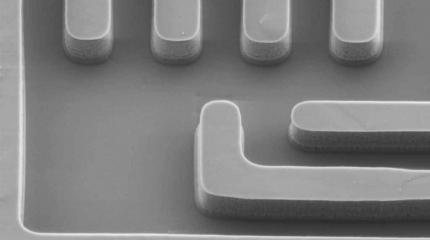

- Single-wafer cleaner for the selective removal of highly inert chemical residues created during the patterning of high-k dielectric metal oxides on Ta, Hf, Zr, Ti barriers.

- Compatible with metal contacts.

- Applications: Ta₂O₅ MIM, Al CAP, Al PER.

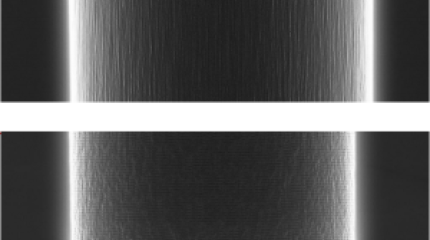

TechniClean BOS390

TechniClean BOS390 has been developed to remove both Bosch fluoropolymer from TSV and P- and N-tone photoresist in a single step.