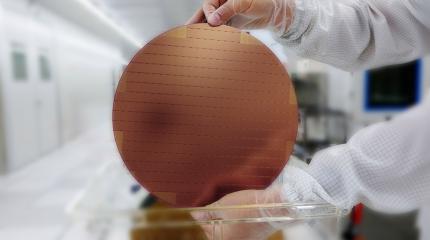

Semiconductor Fabrication & Packaging Chemistry

Technic offers a full range of chemistry for semiconductor fabrication and packaging including electroplating chemistry, photoresist strippers, etchants, and cleaners.

Technic's semiconductor electroplating chemistry, marketed under the name Elevate®, is well-respected globally for innovation and high quality. Elevate® processes offer high-performance electroplating for copper, nickel, tin and precious metals.

Technic supplies photoresist strippers (for both liquid and dryfilm resist), metal etchants and cleaners (ie. post etch residue removers) for a variety of substrates used in wafer level surface preparation.

Technic products provide a number of specific attributes that allow semiconductor manufacturers to remove many process limitations and take their technology to a new level. Our semiconductor fabrication and packaging chemistries are widely used in several advanced packaging platforms including FOWLP (Fan-Out Wafer Level Packaging), Fan-In WLP, Flip Chip and 2.5/3D.

Elevate® Electroplating Chemistries

Copper

Technic supplies a variety of copper plating processes that can meet all industry requirements for multiple semiconductor applications and will provide optimum performance in various production tool sets.

Nickel & Tin

Technic offers a standard nickel process and a boric acid free nickel process. In addition, we offer a silver free solder cap option by providing a pure tin process ideal for advanced packaging. All nickel and tin processes are low maintenance and easy to use.

Precious Metals

Technic's line of precious metal products range from our industry-leading sulfite gold chemistry to the very unique one-step gold-tin alloy plating bath.