Fabrication & Packaging Solutions for PCB Manufacturing

Technic's Printed Circuit Board (PCB) chemistries offer a full range of chemical solutions in PCB manufacturing for technical aspects like zero defects, high aspect ratios, blind micro vias, high Tg material, fine pitch devices, and high temperature processing.

Technic's advanced PCB fabrication and packaging chemistries are engineered to reduce environmental footprints through on site reclaim of metals, as well as the use of concentrates, lead free final finishes and biodegradable products. Due to the cost efficiency of concentrate usage, increased production capacity, and reduced raw material usage, process costs may be significantly reduced.

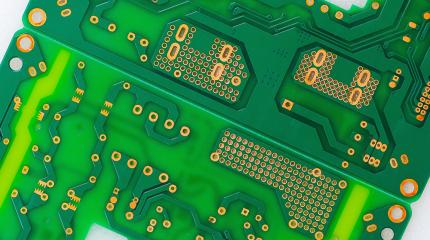

Final Finishes - ENIG ENEPIG EPIG

Technic Final Finishes are qualified and production proven for eutectic, lead-free processing, wire bonding, touch contacts as well as other types of interconnection.

Electrolytic Copper and Tin Plating

Technic offers a variety of Acid Copper and Tin solutions for printed circuit board applications.

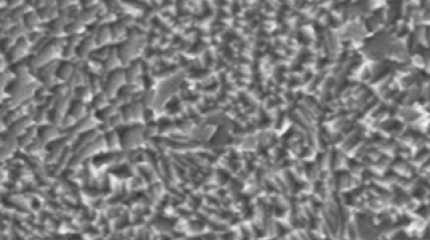

Microetchants

Preparation of the copper surface in PCB fabrication is key to adhesion of resists and any subsequent plating operation. Technic offers a number of microetchant solutions to provide the best surface for success.

Final Finishes - Electroplating

Technic offers an extensive portfolio of final finishing products that are highly effective, efficient, and economical. Please consult your Technic representivie or contact us to discuss your specific application.