Electronic Component & Connector Technologies Offer Key Advantages in Plating Solutions

Plating solutions for Electronic Finishing represent the heart of Technic’s business and technology focus and our core customer base. Optimized to work in harmony with Technic equipment, the process chemistries for these products are as innovative as the industries we serve. Driven by the need for attaining ever-increasing technical performance, Technic’s process chemistries seek to achieve commonality in purpose as described below:

- Innovation: Providing tomorrow’s solutions today through innovative, best-in-class technology.

- Value Generation: Seeking to provide the highest possible technical performance at the lowest possible cost to our customers.

- Environmental Impact: Every new process developed is targeted to reduce the environmental impact compared to the product it replaces

A global leader in connector electrodeposition chemistry, Technic supplies a wide range of products and technologies to meet the ever-expanding range of today’s connector markets.

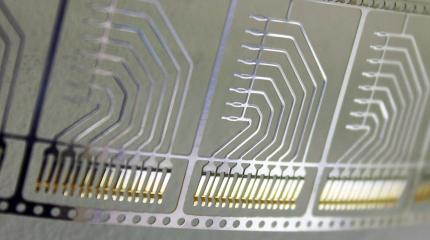

Connectors

Connector plating chemistry and post treatment for Nickel, Gold, Silver, Palladium, Palladium Nickel, Rhodium, Tin and Indium.

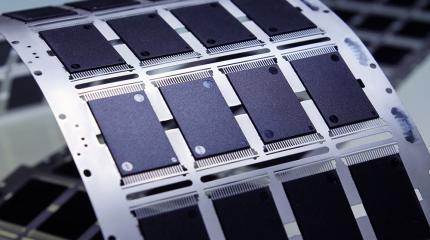

Lead Frames/LED Substrate Applications

Technic offers a selection of advanced solutions that help address a number of key challenges in lead frame and LED substrate processing. Durability, speed, cost, and quality.

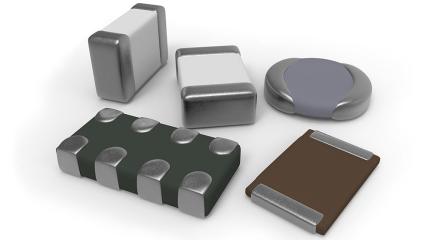

Passive Components

Passive Components Plating Chemistry and Post Treatments for Nickel, Tin, and Tin/Lead.