Connector Plating Chemistry and Post Treatment for Precious Metals, Tin & Tin Alloy

Technic supplies precious metal and tin/tin alloy electroplating processes for all types of electronic connector plating applications. Innovative technologies aimed at reducing or replacing gold usage while enhancing environmental compatibility, operational safety and performance, are the primary focus in new product development.

Goldeneye Nickel BF (Boric Acid Free Plating)

![]()

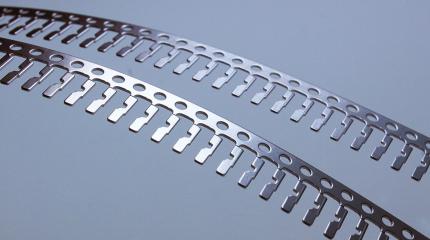

Goldeneye Nickel is a low stress/highly corrosion-resistant nickel plating process capable of operation over a wide range of current densities from a proprietary electrolyte. Noted for its superior thickness distribution, improved corrosion-resistance, and lower waste treatment costs, Goldeneye Nickel can be utilized in reel to reel, rack and barrel plating applications. Goldeneye Nickel BF provides all the advantages of Goldeneye Nickel from a boron-free electrolyte.

Techniphos 615 (High Speed, High Phosphorous Electrolytic Nickel Alloy Process)

![]()

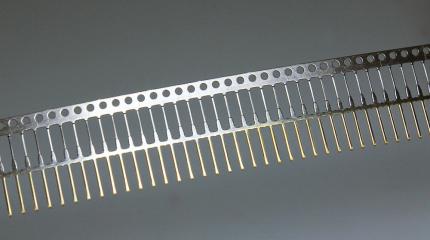

Techniphos 615 is a boric acid-free electrolytic nickel/phosphorous (NiP) plating process that produces >10 % phosphorous over a wide current density range. Unlike typical NiP processes that exhibit low phos content at high current densities, Techniphos 615 represents a truly unique formulation that outperforms anything currently available.

Nickel Electroplating

Goldeneye Nickel

Goldeneye Nickel is a low stress/highly corrosion-resistant nickel plating process capable of operation over a wide range of current densities from a proprietary electrolyte. Noted for its superior thickness distribution, improved corrosion-resistance, and lower waste treatment costs, Goldeneye Nickel can be utilized in reel to reel, rack and barrel plating applications.

Gold Electroplating

Techni Gold® 800/900

Techni Gold® 800/900 are mildly acidic nickel/cobalt brightened gold plating processes designed to minimize gold porosity in electronic connector plating applications. Techni Gold® 800/900 are suitable for use in reel-to-reel and barrel plating applications.

Silver Electroplating

Techni Silver® HCD

Techni Silver® HCD is a silver plating solution designed for reel to reel, strip and spot plating connector applications, with elevated hardness levels compared to conventional silver. Suitable as a gold replacement when used with lubricant-type post-treatment processes.

Durasil® Silver

Durasil® silver provides a hard silver deposit for connector applications. Requires a lubricant for wear-resistant applications.

Palladium Electroplating

Pallaspeed® 990

Pallaspeed® 990 is a chloride-free, low ammonia palladium plating process designed to produce highly ductile, low stress palladium deposits. Suitable for use as an intermediate/barrier layer for high-corrosion resistance applications.

Palladium-Nickel Electroplating

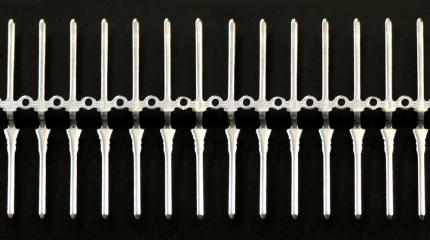

Pallaspeed® Palladium Nickel NFA![]() Pallaspeed® Palladium Nickel NFA is an ammonia and chloride-free, Pd-Ni alloy plating process for connector applications. The composition of the alloy can be adjusted from 70-90% palladium by changing the metal content.

Pallaspeed® Palladium Nickel NFA is an ammonia and chloride-free, Pd-Ni alloy plating process for connector applications. The composition of the alloy can be adjusted from 70-90% palladium by changing the metal content.

Rhodium / Rhodium Alloy Electroplating

Techni White Rhodium

Techni White Rhodium-Ruthenium

The Techni White Rhodium series of rhodium-based finishes is recommended to provide the ultimate in corrosion protection, particularly for satisfying end user imposed electrolytic sweat test requirements.

Tin Electroplating

Techni NF JM8000

Specifically designed for the ultra-high, high, and medium speed deposition of matte tin with minimal tin whisker growth properties, Techni NF JM 8000 provides a lead-free deposit from a methane sulfonic acid electrolyte. The process can be also used in on-line reflow applications.

Techni HT 1000

TechniBrite HT 1000 is a sulfate-based tin electroplating process which produces mirror bright deposits. The process is designed for use in rack and barrel plating applications. The process operates over a wide current density range resulting in increased output and flexibility in production, and is not sensitive to high solution tin concentrations.

Techni NF Tin 400 LA Concentrate

Techni NF Tin 400 LA Concentrate utilizes Grade “A” low-lead tin to create a unique low acid tin methane sulfonate solution that provides benefits in inert anode plating and other applications. Techni NF Tin 400 LA Concentrate enables customers to increase the tin content of the plating solution during bath replenishment without increasing the acid concentration. It can be used in any Technic tin or tin-alloy plating process that uses tin methane sulfonate.

Techniseal AG

![]()

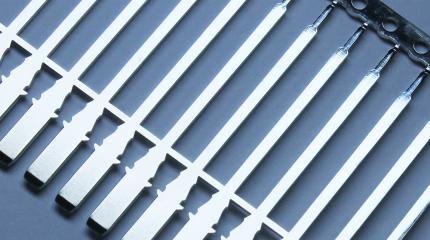

Techniseal AG is a chrome-free cathodic electrolytic passivation system that provides a transparent nano-scale, protective coating on silver which to improves corrosion resistance and minimizes appearance degradation. Techniseal AG protects silver from tarnishing during exposure to heat and/or sulfur corrosion testing from a chrome-free electrolyte. Techniseal AG can also be applied directly on copper for specific applications.

Tarniban® E260

Tarniban® E260 is a post-treatment process which effectively protects tin and tin-alloy deposits from oxidation and discoloration when subjected to thermal conditioning (heating, reflow, etc.)

Tarniban® C48 / C50

Tarniban® C48/C50 minimizes deposit discoloration during storage and provides improvements in solderability performance after steam age pre-conditioning. Tarniban® C48/C50 also minimizes corrosion-induced tin whisker growth caused by high temperature/humidity exposure.

Tarniban® KS II

Tarniban® KS II is an organic thiol post-treatment process which effectively protects silver surfaces from oxidation/tarnishing. It may be used as an immersion only process or applied anodically for increased protection.